Given the economics of today’s oilfield, producing to the last drop has never been more important. And it’s a priority shared by global multinationals, national oil companies and independents alike.

The balance of investment has swung away from capital-intensive projects and firmly onto operating expenditure, leaving operators and their service partners exploring every opportunity to get existing assets working harder.

While Cleansorb breaker systems have repeatedly proven their worth in newly drilled wellbores, the value of these treatments extends far beyond cleaning up pre-production wells.

Years after drilling, a quick workover treatment offers a fast and simple way to breathe new life into mature production wells. A single treatment can not only address residual filter cake that drawdown may not have removed over time, it can also remediate any near-wellbore damage that may have arisen during years of production.

For operators it’s a quick and cost-effective option to maximize existing assets and defer any capital expenditure.

Turning around ten years of constrained production

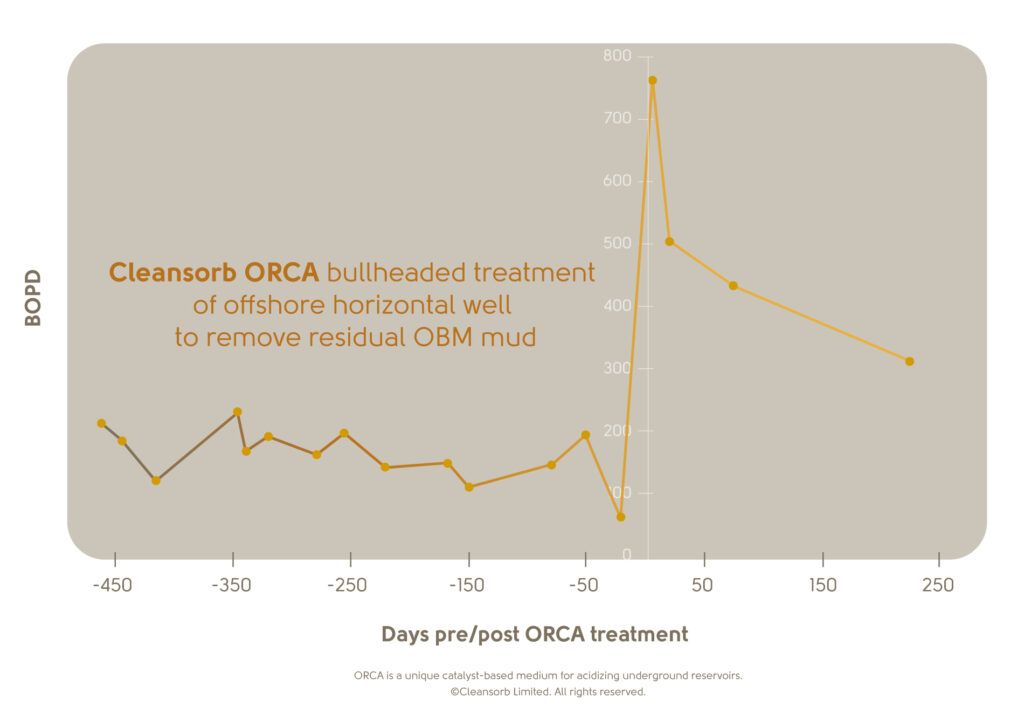

In offshore West Africa, an operator had drilled a horizontal well with a 2,306ft openhole producing interval in a carbonate formation using oil-based drilling mud. The well was acidized with HCl immediately after completion by jet washing with a workstring.

During production, however, logs indicated a lack of fluid flow from over 90% of the openhole section.

Ten years after the well was originally drilled, a Cleansorb workover treatment aimed to initiate production from the non-producing sections of the wellbore to reduce drawdown, minimize gas coning and increase oil production. And, due to a lack of produced gas processing facilities onsite, a further objective was to reduce the gas-to-oil ratio (GOR) where possible.

The treatment fluid was displaced from tubulars into the openhole section, and the well was shut in for 48 hours before being brought back onto production.

The non-hazardous and non-corrosive nature of Cleansorb breakers meant that spent treatment fluids returning to surface could be processed through the operator’s normal water/oil handling and separation systems.

The well experienced a large and sustained increase in oil production – from a pre-treatment low of 20 BOPD to a high of 759 BOPD following workover. At the same time the gas-to-oil ratio (GOR) declined by approximately 40%.

Based on the strength of the data from the first well, the operator then treated the remaining wells in the field.

Delivering production rate increases as high as 550%

An operator in Rajasthan had drilled a series of horizontal openhole wells into a multi-zone sandstone formation completed with standalone screens.

Initial production rates of 2,000 BOPD were at the low end of original reservoir engineering estimates and thought to be caused by damage in the wellbore which had not been cleaned up after drilling.

During workover, a treatment fluid containing Cleansorb breakers was placed across sections of screen using coiled tubing and left in place.

Production rate increases of up to 550% were attained from single-stage treatments with negligible impact on water cut. Again, the operator used Cleansorb on the remaining wells.

The smart option for today’s operators

Cleansorb breakers are low-hazard fluids with low environmental impact that can be easily mixed and pumped using standard oilfield equipment. They’re also safe to transport and handle, making them ideal for operators with small teams, remote offshore wells and aging assets with equipment or infrastructure limitations.

From Asia to Africa, operators around the world are turning to Cleansorb to bring the uniform effect to their production assets. Speak to our team today: it’s never too late to get existing wells working harder for you.

Further reading available at www.spe.org

Follow us on LinkedIn (Cleansorb and Newpark) to stay up-to-date on the latest news, industry trends and developments.

Please get in touch for further information +44 (0)1483 300107 contact@cleansorb.com.